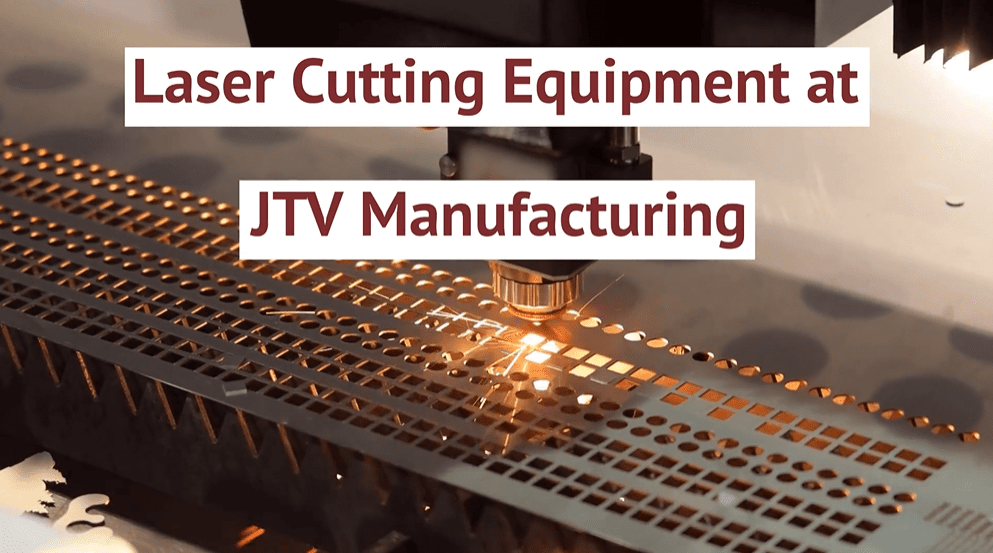

JTV Manufacturing offers industrial laser cutting services for customers in a variety of demanding industries. Founded in 1999, JTV focuses on delivering world-class quality at competitive prices. Our quick turnaround times allow us to meet tight Just-in-Time (JIT) delivery demands for contract manufacturing and short run production needs.

Based out of our 85,000-square-foot production facility in Iowa, JTV is capable of working with carbon steel, stainless steel, aluminum, and other materials up to a maximum thickness of 1¼-inch steel with maximum dimensions of 80 inches by 160 inches. Our expert industrial laser cutting services contribute to our ability to offer turnkey manufacturing services that meet all your metal and custom steel fabrication needs.

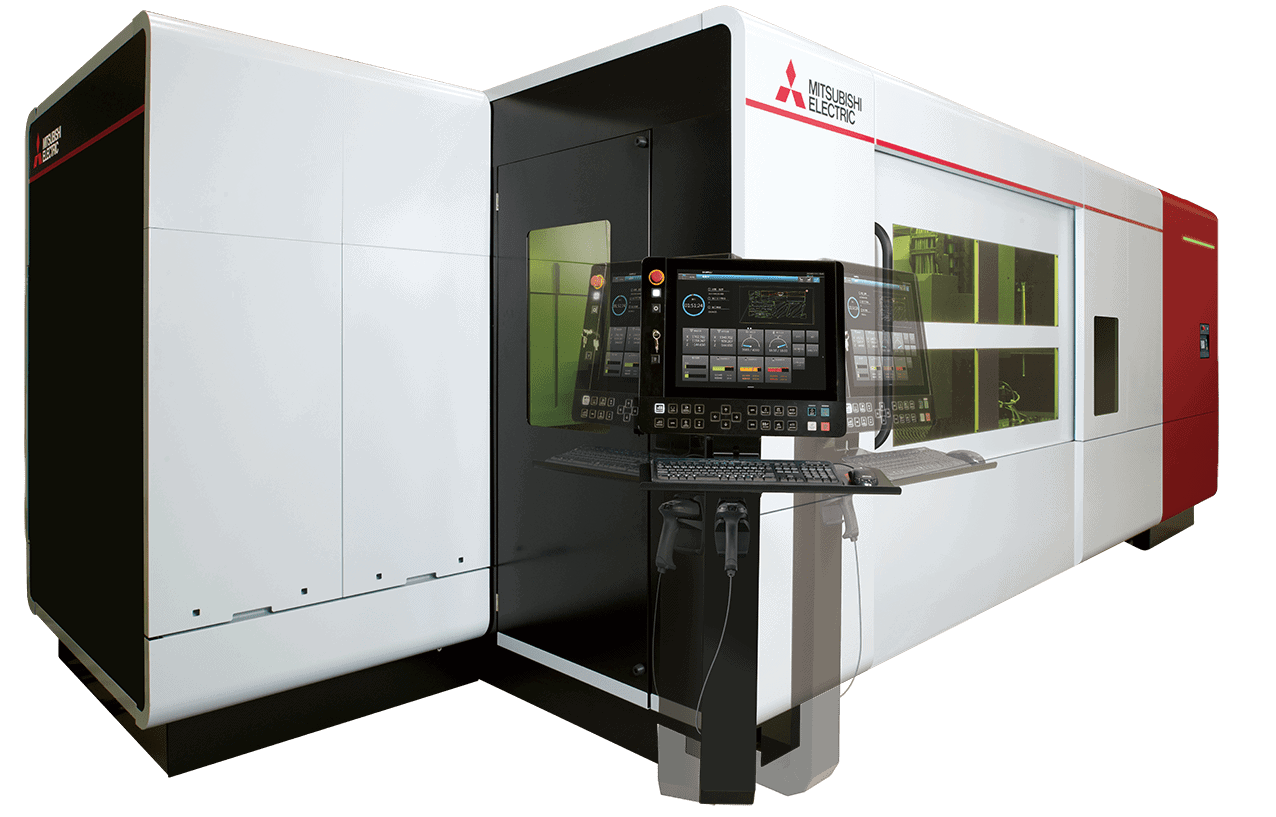

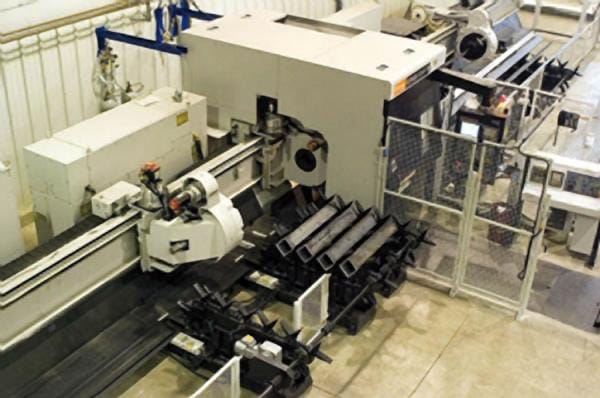

Equipment and Technology

JTV Manufacturing offers industrial laser cutting services supported by a comprehensive lineup of advanced machinery. These systems are chosen for their speed, precision, and adaptability to various material types and thicknesses. From flat sheet laser cutting service to thick plate and structural tubing, this equipment handles a broad range of project requirements efficiently.